Photo Tutorials

Tutorial: Brooklyn Handbag

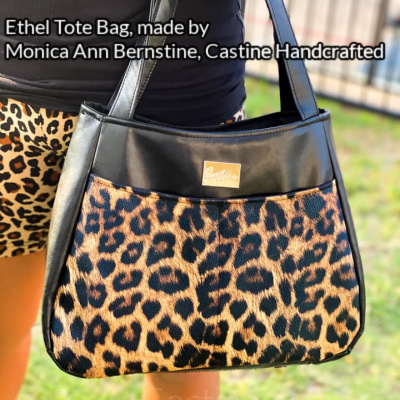

Tutorial: Adding front pockets to Ethel

Tutorial: Evelyn Photo Tutorial

Tutorial: How to Make & Apply Piping (Dottie)

Tutorial: Coraline Clutch Handles

Tutorial: Pleated Coraline Wristlet

Tutorial: Adding Front Pockets to Cate

Tutorial: Blanche Handle Connectors

Tutorial: Adding a Recessed Zipper to India

Tutorial: Colorblocked Coraline

Tutorial: Sewing Vinyl Straps

Tutorial: Vertical Zippered Pocket (Dallas)

Tutorial: Drop in Linings

Tutorial: Double Welt Pocket (Bonnie)

Video Tutorials

Video: Betty Bowler by Birdcage & Thread

Video: Blanche Barrel Bag by Pile O' Fabric

Video: Della Wallet Tutorial (So Sew Easy)

Video: Sewing the Glenda Convertible Clutch (So Sew Easy)

Video: Coraline Recessed Zipper

Video: Eloise Pleated Panels

Video: Installing the Eloise Wrap-Around Zipper

Video: Zippered Pocket (India)

Video: Making Continuous Bias Tape from a FQ

Video: Pearl Wallet Tutorial

General Information

Tips & Tricks: No More Saggy Linings!

Common Interfacings Recommended in Swoon Patterns (with EU replacements)

Tips for Sewing with Oil Cloth, Vinyl & Laminated Cotton

We are in the process of rebuilding the Swoon Patterns Tutorial page.

If you need access to a tutorial urgently, please send us a message via our Contact Form.

Tips & Tricks: No More Saggy Linings!

Common Interfacings Recommended in Swoon Patterns (with EU replacements)

Video Tutorial: How to Make Piping for BagMaking (Sewing Patterns by Mrs H)

Video Tutorial: How to Add Piping to your Bags (Sewing Patterns by Mrs H)

Video Tutorial: How to Use Rivets (Sewing Patterns by Mrs H)

Video Tutorial: How to Add Fold Over Elastic to the top of a Mesh Pocket (Sewing Patterns by Mrs H)

Photo Tutorial: Pinning and Sewing Gussets

Photo Tutorial: Drop-in Linings

Coming soon:

Tips for Sewing with Oil Cloth, Vinyl & Laminated Cotton

Sew Alongs & videos for Swoon Patterns:

Alice Shopper Tote

Annette Handbag & Commuter Tote

YouTube playlist available here: Annette Handbag & Tote Sew Alongs and Tutorials

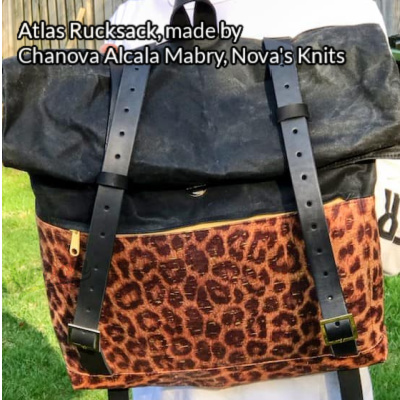

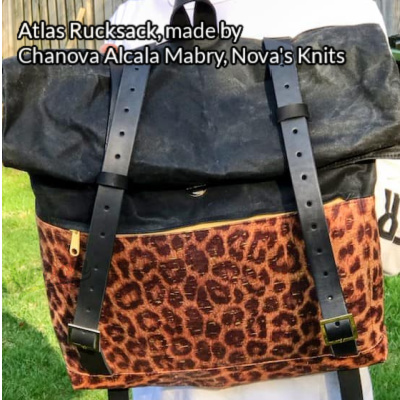

Atlas Rucksack

Bonnie Bucket Bag

YouTube playlist available here: Sew alongs and tutorials for the Bonnie Bucket Bag and drawstring Bonnie

Brooklyn Handbag & Traveler

YouTube playlist available here: Sew alongs and tutorials for the Brooklyn Handbag & Brooklyn Traveler Bag

Camille Camera Bag

YouTube playlist available here: Sew alongs and tutorials for the Camille Camera Bag

Carter Messenger Bag

Celine Zip Tote

Charlotte City Tote

Coraline Clutch

Dakota Tablet Clutch

Dallas Vintage Duffel

Della Wallet Clutch

Denver Backpack & Mini Denver Backpack

YouTube playlist available here: Sew alongs and tutorials for the Denver Backpack and the Denver Mini Backpack

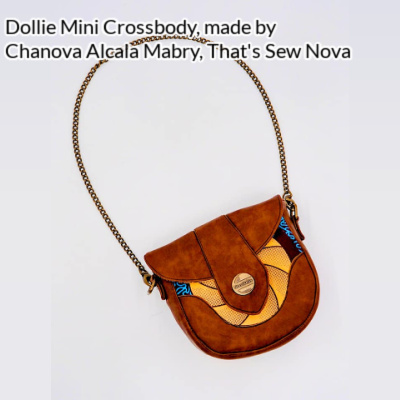

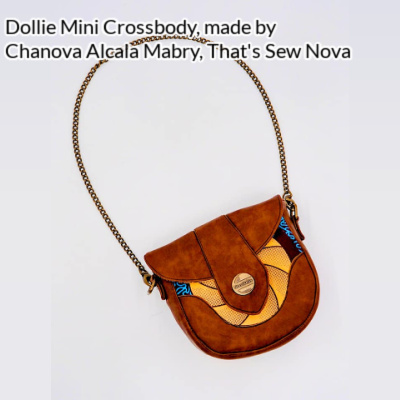

Dollie Mini Crossbody

YouTube playlist available here: Sew alongs and tutorials for the Dollie Mini Crossbody Bag

Donna Vintage Handbag

YouTube playlist available here: Sew alongs and tutorials for the Donna Vintage Handbag

Dorian Messenger Bag

Dorothy Day Tripper

Evelyn Handbag & Market Tote

Expedition Tote

Frankie Handbag & Tote

Gatherer Egg Apron

Glenda Convertible Clutch

YouTube playlist available here: Sew alongs and tutorials for the Glenda Convertible Clutch

Harriet Expandable Tote

YouTube playlist available here: Sew alongs and tutorials for the Harriet Expandable Tote

Heidi Foldover Clutch

YouTube playlist available here: Sew alongs and tutorials for the Heidi Clutch & Wristlet

India Hobo Bag

Julie Ring Top Handbag

Laney Reversible Hobo

Levi Utility Bag

Linette Business Bag

YouTube playlist available here: Sew alongs and tutorials for the Linette Business Bag

Louise Barrel Bag

Lucy Backpack

Mabel Vintage Handbag

YouTube playlist available here: Sew alongs and tutorials for the Mabel Vintage Handbag

Maisie Bowler Handbag

Marianne Clutch & Wristlet

Olive Vanity Bag

Pearl Wallet Clutch

Ramona Mini Hipster

Rosie Crossbody Bag

Roxanne Backpack Tote

Sadie Expandable Bag

Sandra Saddlebag

Sheena Hobo Bag

Sierra Zip Top Handbag

Sophia Swim Tote

Stella Weekender

Summer Festival Sling

Sydney Crossbody

Vivian Handbag & Traveler

Photo Tutorials:

Tutorial: How to make and apply piping to your bag (Dottie Vintage Handbag)

Note: The Dottie Vintage Handbag pattern is retired, however you can use this guide with other purse patterns)

Tutorial: Zip Around Pearl (sew the Pearl Wallet Clutch as a zip around wallet)

Tutorial: Vertical Zippered Pocket (Dallas)

Coming soon:

Tutorial: Brooklyn Handbag

Tutorial: Adding front pockets to Ethel

Tutorial: Evelyn Photo Tutorial

Tutorial: Coraline Clutch Handles

Tutorial: Pleated Coraline Wristlet

Tutorial: Adding Front Pockets to Cate

Tutorial: Blanche Handle Connectors

Tutorial: Adding a Recessed Zipper to India

Tutorial: Colorblocked Coraline

Tutorial: Sewing Vinyl Straps

Tutorial: Drop in Linings

Tutorial: Double Welt Pocket (Bonnie)